In a lubrication system, one of the most common contaminates found is water. The result is detrimental in many ways to the general effectiveness of the oil. When water is present, it can decrease the longevity of the oil and cause the equipment to falter then fail. To prevent this, companies utilize an oil water separator. One of the two basic types is a coalescing plate separator.

What Are Coalescing Plate Oil Water Separators?

Water and other substances are harmful to machinery. Its presence in the oil can accelerate oxidation while encouraging the formation of foaming and sludge. Water also encourages corrosion. All such actions can create serious issues for machinery of all types. At the same time, the contamination of even wastewater by oils is harmful to the environment.

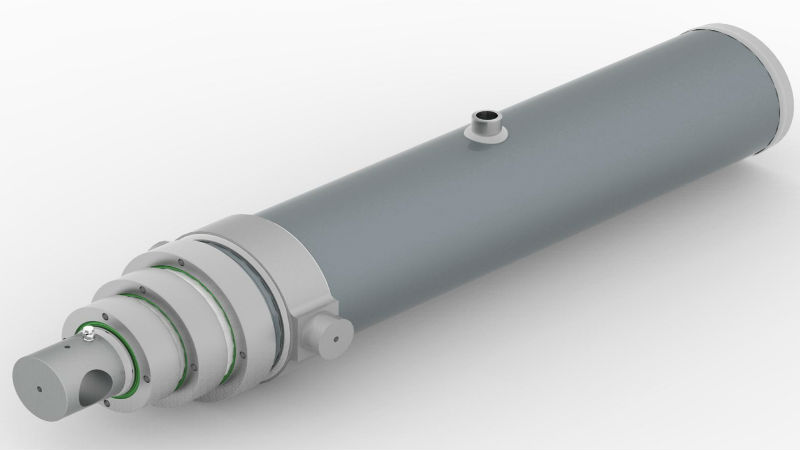

Coalescing plate oil water separators act to prevent the occurrence of these problems. This type of oil separator gets its name from its design. Two coalescing media packs sit at two stages. Combining the plates with gravitational forces results in the separation of the oil from the water. Small oil droplets adhere to the surface space, rising to the surface for skimming into a container designated for this purpose.

Applications and Uses for an Oil Water Separator

Diverse industries employ a coalescing plate oil water separator. Among the various applications and uses are for the following:

- Car washes

- Construction sites

- In areas for cleaning/washing down equipment and various pieces of machinery

- Industrial loading bays

- Re-fueling sectors

- Service station bays and areas

- Transformer bunds

- Wash down bays for various vehicles

- Workshops and stations for various industrial, mechanical and mining concerns

These industrial concerns and businesses realize the necessity of installing the right type of oil water separator. This improves the operation of machinery. It also reduces the number of contaminants that could escape into the environment.