As a machine shop owner, you’re likely hyper aware of the amount of coolant your shop uses. It’s a big expense for your shop, but one you cannot avoid. However, you can reduce your coolant costs by using an oil water separator and recycling your coolant.

By installing an oil water separator, you’ll be able to recycle your coolant several times before disposing of it. This can reduce your coolant usage by up to 80% over time. Even though you will have some costs associated with installing the oil water separator, you’ll recoup this very quickly, and then the savings will go directly to your bottom line.

Reduced use of coolant also means less coolant to dispose of. Since environmental regulations require that coolant be disposed of in a manner that is safe, you’ll also see a cost-saving in this area, as well as an increase in your company’s environmental safety.

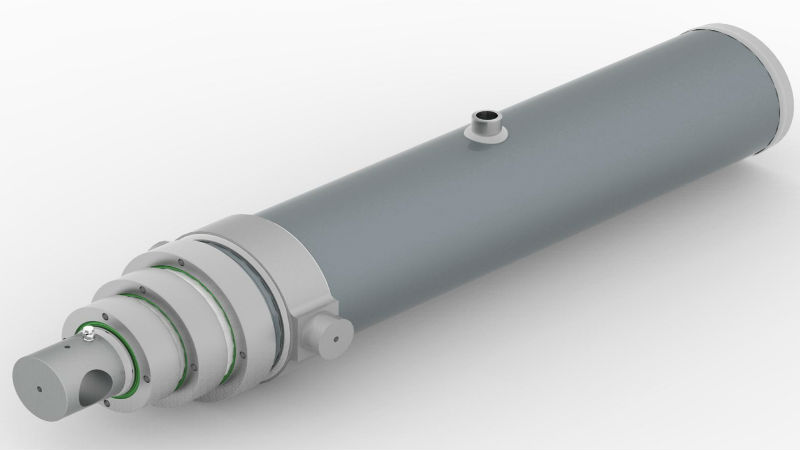

Talk with your distributor about installing an oil water separator for your shop. They can offer a system that is durable, long lasting and easy to maintain. You’ll find that having this system in your shop is works well with the flow of your operations. Choose a vendor that is committed to supplying durable and cost-effective solutions for businesses of all sizes.

You’ll find many benefits from having an oil water separator in your shop. The air in your facility will feel cleaner for your employees, and the shop itself will be cleaner, as well. You can also be proud of the fact that your shop will be operating in a more environmentally friendly manner. But, most of all, you’ll be happy with all the money you’ll save by significantly reducing the amount of coolant you’ll purchase and dispose of every month.