When you check out the many different kinds of aluminum alloys on the market today, you will notice a lot of options. For instance do you choose a 5000 series or a 6000 series like 6061 aluminum? There are so many options it can be a bit overwhelming, and here is information on some of the most common alloys to help you make a decision.

5000 Alloys

The 5000 series aluminum alloys utilize magnesium as the main element. When magnesium is added to aluminum it produces a metal with excellent strength but is not heat treatable. This kind of aluminum is not difficult to weld and provides very good anti corrosion properties. In fact, its corrosion resistance is so strong it is used for many kinds of marine applications. Here are some common options:

* 5052 – street signs, cooking utensils, fuel tanks

* 5005 – roofing, storage tanks, electrical wiring

* 5086 railroad cars, boat hulls, drilling rigs

* 5054 truck bodies, boilers, various marine applications

6000 Alloys

6000 series aluminum alloy uses both magnesium and silicon. The most common product is 6061 aluminum. Unlike 5000 series alloys, 6000 can be hardened to some degree. This alloy can also be welded and is often used for machining.

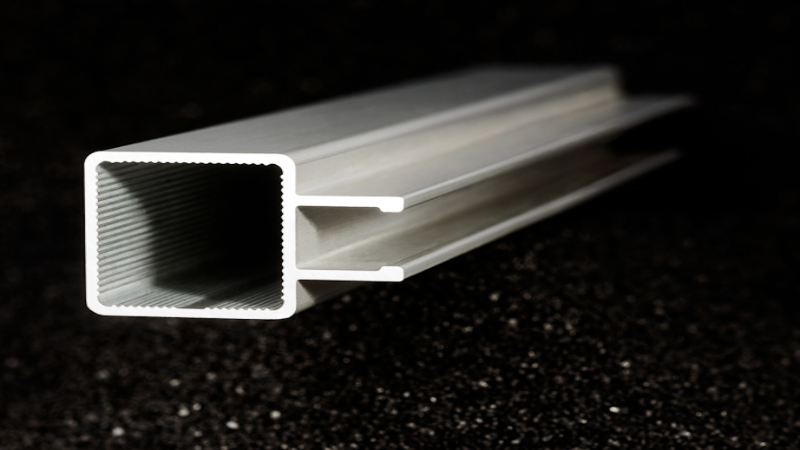

When it comes to aluminum extrusion products, 6000 series is the preferred choice. In fact, 6061 aluminum is the most used product when it comes to extrusion. This process can create many different shapes and sizes, including bars, tubing, channels and roofing materials.

6061 aluminum sees many different uses like aircraft, auto parts, scuba tanks and even common everyday aluminum cans. 6061-T6 has been tempered for added strength and is used in bicycle frames, docks, fishing reels and many other things.

7000 Alloys

7000 series aluminum is designed for exceptional strength. It is created with many different alloys including chromium, magnesium, iron and copper. Two of the most common alloys produced are 7005 and 7075. 7000 series is not hardened in the same way as 6061 aluminum. Because of similar properties to 6061 it is used to make high quality bicycle frames because it is somewhat harder.

Zinc is what makes 7075 aluminum so special. Zinc provides it with an enormous amount of strength and hardness, and it’s comparable to steel in some cases. In fact, 7075 is often used in place of steel when a great deal of corrosion resistance is desired. 7000 series aluminum sees use in the aviation, transport and marine industries. In addition it can be polished to a shine and is used in the M16 rifle.