A high shear mixer is also known as a shear reactor, which is used to amalgamate, homogenize, or grind immiscible fluids with other elements. Go through this article to learn about the characteristics and other important facts about high shear fluid processors.

High Shear Fluid Processors Characteristics

• High rotor tip speeds

• High shear rates

• Localized rates of energy dissipation

• High power consumption

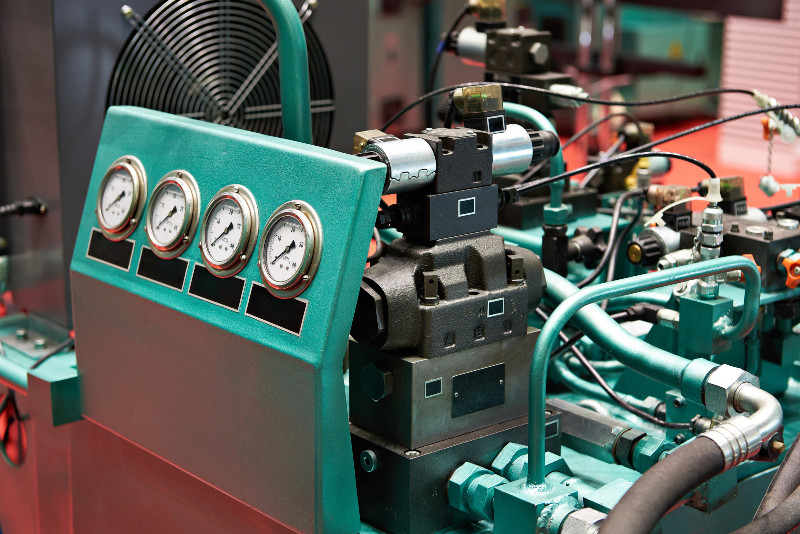

The movement of the rotating parts in relation to the stationary parts of a mixer can generate the shearing forces mixing components. The parts that can rotate make a impeller, screw or paddle sets. On the other hand, the stationary parts, are the tank’s walls and chamber. Also, they can be found in some specific designs, baffles, and vanes.

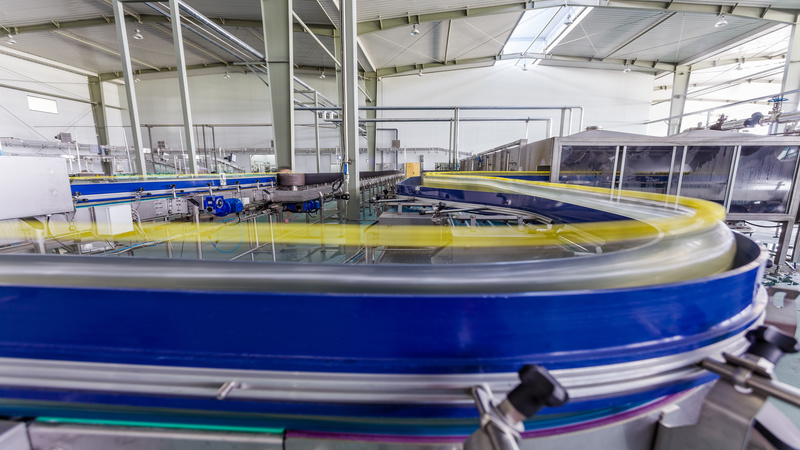

In the manufacturing industry, you can find ample use of high shear fluid processors. Apart from the manufacturing industry, these are most frequently used in pharmaceuticals, cosmetics, and plastic industries. Also, you can find principles of high shear fluid in chemical and petrochemical plants where they are applied for aiding in the reaction method.

Types of High Shear Fluid

Have a look at some key types of high shear fluid processors:

• Batch high shear mixers

• In-line high shear mixers

• Powder induction high shear mixer

• High shear granulators

• Ultra-high shear mixers

Before using high shear fluid, it is important for you to know its characteristics and usages. When handled by experienced hands, these devices can provide outstanding results. No matter in which industry it is being used, the right use of these devices can make manufacturing flawless. Also, the use of these processors makes the production process faster.