In production, the priorities are precision and efficiency. The thread forming machine screw is one aspect that really helps to achieve these goals. This type of screw is fairly useful in many different industrial applications because it generates strong and long-lasting threads without the need for cutting tools.

Screw Forming Machines: Mechanisms

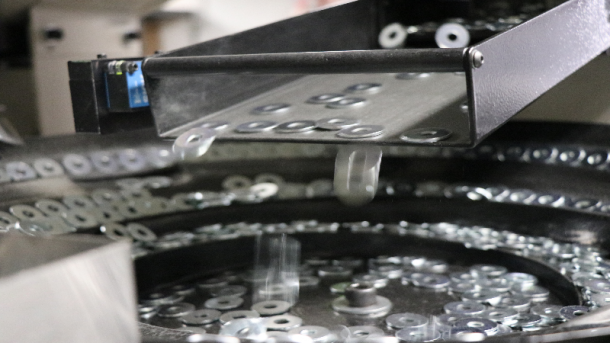

Specially designed machine screws are crafted to create internal grooves in materials such as metal, plastic, or composite substances. Unlike conventional screws, which carve grooves into the material, these specialized fasteners displace the material to form the grooves. This approach not only enhances thread strength but also bolsters the overall integrity of the assembly. The process results in reduced material waste and simplifies the manufacturing technique. The unique design of these screws compresses the material instead of cutting it, leading to robust threads. This method contributes to a higher-quality finish and increases resilience to vibration and stress, making it ideal for high-volume manufacturing where consistency and accuracy are crucial.

Benefits and Applications

Thread forming machine screw are used extensively in electronics, automotive, and aerospace industries due in great part to their dependability and performance. Their ability to generate threads without cutting allows them to fit applications where the material is too delicate for other threading methods. Their application also simplifies manufacturing processes, helping to increase productivity and cut costs. These screws also have the benefit of reducing the likelihood of material deformation or damage, which is usually caused by cutting threads. This characteristic makes them suitable for applications where material integrity is rather important.