In electrical applications, having the right materials for each aspect of the job is important. When it comes to the bus bar in use, most electrical contractors have made the transition from copper to aluminum.

The reasons for this transition include the readily available nature of aluminum as compared to copper. This availability means a lower price for the project without any loss in conductivity or versatility. Of course, it will be essential to use only electrical grade aluminum bus bar for optimal performance in these applications.

Choosing the Correct Option

There are different categories of electrical grade aluminum bus bar that make one particular alloy better than another. Making a choice between the various options requires an understanding of the specific properties of the alloy as well as a good working knowledge of what is needed with regards to machinability and working with the bus bar within the electrical system.

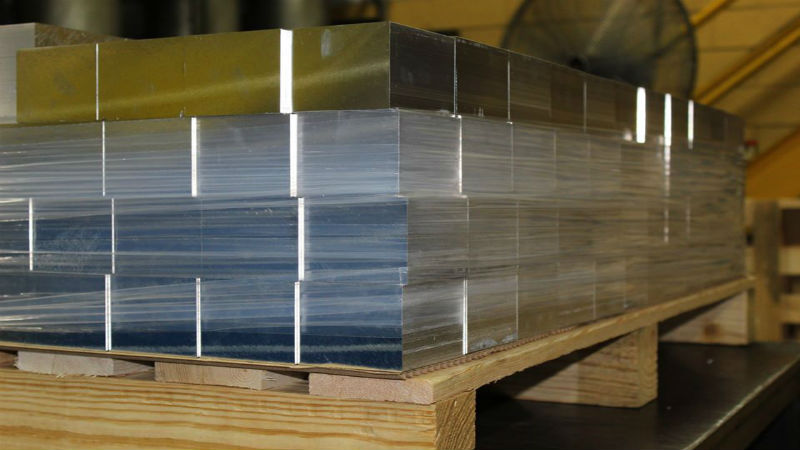

There are two different options when it comes to specifications with the bus bar. One specification is the structural grade of bus bar while the other is the electrical grade aluminum bus bar. The key factors that make one alloy a superior option and of the electrical rather than structural grade is about conductivity, which itself is a factor of the type of aluminum used and the hardness.

This information will be relevant regardless of the application. The bus bar will be used in a wide range of applications where power transmission is required, including power stations and both AC and DC applications.

Selecting A Supplier

Shop around online before choosing a supplier for electrical grade aluminum bus bar of either electrical or structural grades. Consider the value added services the supplier provides as this can allow you to order the bus bar to be precision cut to the desired lengths as well as any machining of finishing you may require.