Startup companies and OEMs have to make a decision about the type of work that is done in-house, and the work that is outsourced. In the past, completing work in-house was seen as the best option, but today the focus is on outsourcing to reliable contract manufacturers and partners.

Specialized types of services, such as precision metal machining, are a particularly good choice for outsourcing. These services require not only specialized equipment, but experienced equipment operators.

Capacity

In working with a top shop providing metal machining, capacity for the order should never be a question. This is very important for startup companies and new product lines when ramping up production to meet demand as markets increase is an essential factor to consider.

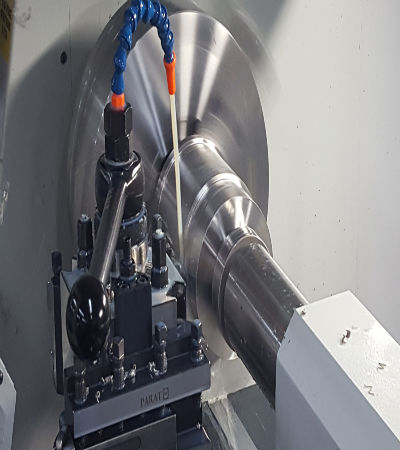

State-of-the-art Equipment

With precision CNC metal machining, the cost of updating, maintaining and purchasing state-of-the-art equipment is cost-prohibitive for an OEM. The specialty shops have the production volume and the need for cutting edge equipment to make it worth their while to operate using the best possible machining systems and centers.

Cost Savings

Outsourcing machining is the only way to ensure you know the cost of the parts prior to production. Experienced machining services can sometimes provide lower cost production options, which actually benefits the OEM significantly with the current order as well as for future orders.

Reliability

It is important to research the machining service. Look for companies that have experience in your industry as a starting point. It is also essential to check the companies turnaround time on orders, and their ability to provide orders to your schedule requirements.

Finding the right company to partner with for the production of machined metal parts is not always easy. However, taking the time and considering all the options is the only way to find the ideal service to work with for your machining needs.